FACTORY AUDIT SERVICES

Ensuring Compliance, Quality & Reliability. Our service excellence covered within “Factory Audit,” “Supplier Audit,” and “Compliance Audit”

📘 1. What is Supplier Evaluation Audit / Vendor Compliance?

A Supplier Evaluation Audit (SEA), also referred to as a Vendor Compliance Audit, is a structured and systematic assessment of a supplier’s ability to meet contractual, ethical, regulatory, environmental, health & safety and quality standards.

Its main purpose is to ensure suppliers can reliably deliver products or services in alignment with global buyers’ expectations and industry compliance requirements, reducing risks before business engagement.

⚙️ 2. Criteria Covered / Typical Areas Assessed

| Category | Key Checks | Buyer’s Benefits |

| Legal & Business | Business licenses, tax records, ISO certifications | Legitimacy & Governance: Verify legal registration, financial health, and corporate policies. |

| Quality & Process | SOPs, process controls, ISO 9001 compliance | Quality Management: Ensure consistent product quality. Assess production processes, quality control, and certifications. |

| Capacity & Capability | Workforce skills, production volume, machinery | Operational Readiness: Confirm production capacity, equipment, workforce competency, and scalability. Reliable order fulfillment |

| Ethical & Social | Labor rights, anti-bribery policies, SA8000/SMETA compliance | Social Responsibility: Ensure adherence to labor standards, fair wages, and human rights. Protect brand reputation |

| Environmental | Waste management, energy usage, environmental certifications | Sustainability Compliance: Evaluate waste management, energy efficiency, and environmental practices. |

| Safety & Security | Fire safety, site security, workplace hazards | Workplace Safety: Verify safety measures and minimize operational risks. |

🧭 3. Comprehensive Supplier Evaluation Audit usually Covered

• Legitimacy & Governance – Legal registration, financial health, management structure, and corporate policies.

• Quality & Process – Manufacturing processes, quality control systems, certifications (ISO, CE, etc.), and defect management.

• Capacity & Capability – Production capacity, equipment, technical expertise, workforce competency, and scalability.

• Ethical & Social Compliance – Labor standards, human rights, fair wages, and social responsibility programs.

• Environmental & Safety Practices – Waste management, pollution control, workplace safety, and sustainability initiatives.

🎯 4. Objectives & Key Benefits of Supplier Evaluation Audit

A Supplier Evaluation Audit (SEA) is conducted with the goal of ensuring that suppliers meet international quality, compliance, and performance standards. It provides a structured framework to evaluate suppliers’ operations while promoting continuous improvement and transparency.

Core Objectives

| Objective | Purpose / Expected Outcome |

|---|---|

| ✅ Verify Compliance | Ensure suppliers adhere to international regulations, industry standards, and safety requirements. |

| 🧩 Assess Quality Systems | Examine production processes, quality control procedures, and certifications to maintain consistent product quality. |

| ⚙️ Evaluate Capacity & Capability | Confirm the supplier’s operational readiness, workforce skills, and resource availability to meet buyer demand. |

| 🚨 Identify Risks Early | Detect potential operational, financial, or ethical risks that may impact supply chain reliability. |

| 🌱 Support Supplier Development | Offer corrective actions and improvement plans to enhance efficiency, ethics, and long-term performance. |

Key Benefits of Conducting Supplier Evaluation Audit

| Benefit | Description / Impact |

|---|---|

| 📉 Reduced Supply Chain Risk | Prevent supply disruptions by identifying non-compliance or underperformance early. |

| 🏭 Improved Product Quality | Ensure products consistently meet agreed specifications and global standards. |

| 🔍 Enhanced Supplier Transparency | Gain clear insight into supplier operations, management practices, and compliance systems. |

| 🌍 Ethical & Environmental Assurance | Confirm adherence to labor laws, human rights, environmental standards, and corporate social responsibility guidelines. |

| 💡 Informed & Strategic Decision-Making | Empower buyers with accurate supplier data to make confident sourcing and partnership decisions. |

🕓 6. When to Conduct the Supplier Audit

Before Onboarding a Supplier – Confirm compliance before partnership.

Periodically During Partnerships – Monitor performance and compliance.

After Critical Incidents – Assess suppliers following issues or breaches.

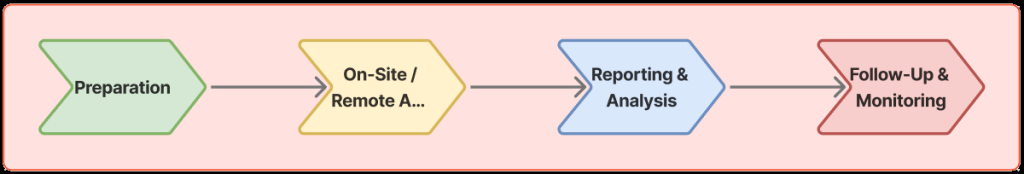

📊 7. Steps to Conduct Supplier Evaluation Audit

Process Flow

| Stage | Key Activities |

|---|---|

| Preparation | Collect supplier documents (certifications, financials, SOPs); Define scope & criteria; Develop tailored checklist. |

| On-Site / Remote Audit | Inspect facilities/offices; Interview staff; Verify documentation; Observe operations. |

| Reporting & Analysis | Record findings; Rate performance; Identify non-conformities; Recommend improvements. |

| Follow-Up & Monitoring | Set corrective deadlines; Reassess periodically; Track performance improvements. |

✅ 8. Supplier Evaluation Checklist & Rating

| Category | Sample Audit Items | Rating / Scoring Method |

|---|---|---|

| Legal & Business | Licenses, tax compliance, ISO certifications | 0–5 |

| Quality & Process | SOP adherence, process control, ISO compliance | 0–5 |

| Capacity & Capability | Workforce skills, production volume, equipment | 0–5 |

| Ethical & Social | Labor rights, anti-bribery, SA8000/SMETA | 0–5 |

| Environmental | Waste management, energy usage, certifications | 0–5 |

| Safety & Security | Fire safety, site security, workplace hazards | 0–5 |

Rating Key:

5 – Excellent / Fully Compliant

4 – Good / Minor Observations

3 – Satisfactory / Needs Improvement

2 – Poor / Major Gaps

1 – Critical / Non-Compliant

0 – Not Applicable or Missing

⚖️ 9. Common Challenges & Mitigation

| Challenge | Mitigation |

|---|---|

| Incomplete or False Documentation | Verify authenticity via databases or third-party validation |

| Supplier Resistance | Explain purpose and benefits; promote collaboration |

| Diverse Global Standards | Balance local vs global compliance |

| Complex Supply Chains | Trace sub-suppliers and subcontractors |

| Subjective Assessments | Use rating systems and standardized checklists |

🧠 10. Best Practices for Effective Supplier Evaluation Audit

• Plan Thoroughly

• Use Standardized Checklists

• Train Audit Teams

• Engage Suppliers Positively

• Leverage Technology

• Document Everything

🔍 11. Real-World Example: Electronics Manufacturing

Scenario:

A European buyer seeks to source electronic components from an Asian supplier.

Audit Steps:

Pre-audit: ISO certificates, financials, SOPs

On-site: Checked quality testing labs, inventory, and traceability

Interviews: Verified labor and safety policies

Findings: Missing QC records → Recommended digital logs & training

Outcome:

Supplier implemented corrective actions; long-term partnership established with improved compliance confidence.

🏭 1. What is Capacity & Capability Audit?

A Capacity & Capability Audit (CCA) is a systematic evaluation of a supplier’s operational readiness, workforce skills, and technical competence. It ensures factories can deliver products on time, at the required quality, and at scale, aligning with global buyer expectations.

Purpose: Minimize risks, confirm operational efficiency, and ensure reliable supplier performance before business engagement.

⚙️ 2. Key Areas Assessed

| Category | Key Checks | Buyer’s Benefits |

|---|---|---|

| Production Infrastructure | Machinery, production lines, maintenance logs | Assess efficiency and minimize downtime |

| Workforce Capability | Skill levels, training, workforce planning | Ensure competency, stability, reliability |

| Technical Competence | Equipment calibration, R&D, process automation | Validate know-how and innovation capacity |

| Capacity Utilization | Lead times, throughput, order handling | Confirm readiness for bulk/repeat orders |

| Supply Chain & Logistics | Raw material sourcing, warehouse management | Evaluate resilience and on-time delivery |

| Quality & Process | SOP adherence, defect tracking, in-line inspections | Maintain consistent quality |

🧭 3. Comprehensive Audit Coverage

Production Capacity: Maximum output and planning efficiency

Equipment & Technology: Maintenance and process automation

Workforce Competence: Training, skills, and retention

Process Control & Efficiency: Workflow optimization

Scalability & Flexibility: Ability to manage demand surges

Supply Chain Stability: Raw materials and logistics readiness

🎯 4. Objectives & Key Benefits

Core Objectives

| Objective | Purpose / Outcome |

|---|---|

| ✅ Verify Production Readiness | Ensure factory is ready before order placement |

| ⚙️ Assess Technical Capacity | Evaluate machinery, automation, and R&D |

| 👷 Evaluate Workforce Competence | Confirm skilled, trained, and stable staff |

| 📈 Measure Scalability | Determine ability to handle higher volumes |

| 🚨 Identify Bottlenecks | Detect operational limitations for corrective action |

| 🌱 Support Process Improvement | Recommend technology, training, and efficiency upgrades |

Key Benefits

📉 Reduced Supply Chain Risk: Identify limitations early

🏭 Improved Product Quality: Consistent output aligned with buyer standards

🔍 Enhanced Supplier Transparency: Clear insight into operational readiness

🌍 Ethical & Environmental Assurance: Compliance with labor, safety, and environmental standards

💡 Strategic Sourcing Decisions: Confident supplier selection

🕓 5. When to Conduct

Before Contract Finalization – Confirm readiness

During Supplier Qualification – Assess new suppliers

Before New Product Launches – Validate production lines

After Expansion or Growth – Check capacity against increased demand

📊 6. Audit Process Flow (Infographic)

Flow Chart Style:

Preparation → On-Site / Remote Audit → Reporting & Analysis → Follow-Up & Monitoring

Stage Highlights:

Preparation: Collect documents, define scope, prepare checklist

On-Site / Remote Audit: Observe production, interview staff, verify processes

Reporting & Analysis: Document findings, rate performance, recommend improvements

Follow-Up & Monitoring: Set deadlines, reassess periodically, track progress

✅ 7. Capacity & Capability Rating

| Assessment Area | Indicators | Score (0–5) |

|---|---|---|

| Equipment & Technology | Age, maintenance, efficiency | 0–5 |

| Workforce Skills | Training, supervision, retention | 0–5 |

| Production Efficiency | Throughput, downtime, yield | 0–5 |

| Scalability | Flexibility for volume changes | 0–5 |

| Logistics & Materials | Inventory control, lead time | 0–5 |

Rating Key:

5 – Excellent / Fully Capable

4 – Good / Minor Gaps

3 – Satisfactory / Needs Improvement

2 – Poor / Major Bottlenecks

1 – Critical / Not Capable

0 – Not Applicable / Missing

Visual Tip: Use horizontal bars or color-coded icons (green/yellow/red) for an instant performance snapshot.

⚖️ 8. Common Challenges & Mitigation

| Challenge | Mitigation |

|---|---|

| Incomplete Documentation | Verify via official or third-party sources |

| Supplier Resistance | Explain benefits; promote collaboration |

| Diverse Standards | Balance local & global regulations |

| Complex Supply Chains | Trace sub-suppliers and subcontractors |

| Subjective Assessment | Use standardized checklists & ratings |

🧠 9. Best Practices

Plan objectives, scope, and timeline clearly

Use standardized checklists

Train audit teams with technical and regulatory knowledge

Engage suppliers positively

Leverage digital dashboards and scoring tools

Document photos, reports, and evidence for traceability

🔍 10. Real-World Example: Electronics Manufacturing

Scenario: European buyer sourcing from an Asian supplier.

Audit Steps:

Pre-audit: ISO certificates, financials, SOPs

On-site: Checked production lines, labs, inventory, traceability

Staff Interviews: Verified labor and safety compliance

Findings: Missing QC records → Recommended digital logs and staff training

Outcome:

Corrective actions implemented

Long-term partnership established with confidence in capacity and capability

🏭 1. What is a Factory Technical Assessment (FTA)?

A Factory Technical Assessment (FTA) is a detailed evaluation of a supplier’s production facility, machinery, technical workforce, and operational processes. It ensures that the factory can efficiently produce high-quality products at the scale, speed, and compliance levels expected by international buyers.

Purpose:

Verify operational readiness

Assess technical capabilities

Evaluate process efficiency

Identify risks before production starts

FTA is particularly critical for high-volume or specialized manufacturing, where operational issues can result in delays, quality defects, or non-compliance.

⚙️ 2. Key Areas Assessed / Buyer Benefits

| Category | Key Checks | Buyer Benefits |

|---|---|---|

| Production Infrastructure | Machinery, automation, layout, spare parts availability | Confirm the factory can meet production demand reliably |

| Process & Workflow | Production lines, SOPs, workflow efficiency, defect management | Ensure process efficiency and minimize errors |

| Technical Expertise | Workforce skills, certifications, training programs | Competency assurance for handling complex production |

| Maintenance & Calibration | Equipment maintenance schedules, calibration records | Reduce downtime and prevent production bottlenecks |

| Technology & Innovation | Digital integration, automation, software use | Evaluate capability for modern manufacturing and scalability |

| Quality Control Systems | QC labs, testing equipment, process adherence | Maintain consistent product quality and compliance |

| Capacity Planning | Order fulfillment capacity, scalability | Ensure factory can handle peak demand without compromising quality |

| Energy & Utilities Management | Power backup, energy efficiency, water treatment | Operational sustainability and reduced production risk |

| Safety & Compliance | Fire safety, machinery safety, occupational hazards | Ensure workforce safety and compliance with regulations |

| Environmental Practices | Waste management, emissions control, certifications | Support sustainable and responsible sourcing |

🧭 3. Comprehensive Factory Technical Assessment Coverage

A thorough FTA includes:

Production Infrastructure: Evaluate machines, automation, layout, and spare parts availability.

Process & Workflow: Examine SOPs, defect management, and production sequencing.

Technical Expertise: Assess staff skill levels, certifications, and training programs.

Maintenance & Calibration: Review preventive maintenance schedules and calibration logs.

Technology & Innovation: Inspect digital systems, automation, and integration capability.

Quality Control Systems: Evaluate QC labs, testing procedures, and defect reporting.

Capacity Planning: Determine ability to fulfill orders on time and scale production efficiently.

Energy & Utilities Management: Check for uninterrupted operations and energy efficiency.

Safety & Compliance: Inspect fire safety, machinery safety, PPE use, and occupational compliance.

Environmental Practices: Evaluate waste management, environmental certifications, and sustainability measures.

🎯 4. Objectives & Key Benefits of Factory Technical Assessment

Core Objectives:

| Objective | Purpose / Expected Outcome |

|---|---|

| ✅ Verify Production Readiness | Ensure the factory has the required operational capacity |

| ⚙️ Assess Technical Competence | Confirm workforce skills and machinery suitability |

| 🏭 Evaluate Process Efficiency | Identify workflow bottlenecks and optimize operations |

| 🚨 Identify Risks Early | Detect technical, operational, or quality risks before production starts |

| 🌱 Support Factory Improvement | Provide actionable recommendations to improve efficiency, compliance, and quality |

| 💡 Ensure Scalability | Assess ability to expand production without compromising quality |

| 🔧 Maintenance & Reliability Check | Evaluate machinery condition and preventive maintenance processes |

Key Benefits for Buyers:

| Benefit | Description / Impact |

|---|---|

| 📉 Reduced Operational Risk | Minimize production delays, equipment failure, or capacity gaps |

| 🏭 Improved Production Quality | Maintain high-quality standards consistently |

| 🔍 Enhanced Operational Transparency | Gain insight into production capability, processes, and technical readiness |

| 🌍 Technical & Environmental Assurance | Verify sustainable, safe, and compliant operations |

| 💡 Informed Decision-Making | Make confident sourcing decisions based on objective technical evaluation |

| ⚡ Faster Time-to-Market | Ensure suppliers can meet production schedules efficiently |

🕓 5. When to Conduct Factory Technical Assessment

Before Supplier Onboarding: Verify readiness before finalizing contracts

Before Mass Production: Ensure capacity and technical competence

After Facility Upgrades: Assess machinery, process, or technology updates

Post-Incident: Re-evaluate after breakdowns, accidents, or production deviations

During Long-Term Partnerships: Periodic assessments to maintain operational excellence

📊 6. Steps to Conduct Factory Technical Assessment

Process Flow

| Stage | Key Activities |

|---|---|

| Preparation | Collect factory documents (machinery lists, SOPs, maintenance logs); define scope & audit criteria; prepare checklist |

| On-Site / Remote Assessment | Inspect production lines and machinery; interview staff; verify SOPs, QC systems, and workflow; observe operations |

| Reporting & Analysis | Record findings; rate technical and operational readiness; highlight risks; recommend corrective actions and improvements |

| Follow-Up & Monitoring | Set deadlines for corrective actions; reassess periodically; track improvements in workflow, capacity, and quality |

Include a flow chart here linking all four stages visually.

✅ 7. Factory Technical Checklist & Rating

Checklist ensures:

Uniform evaluation across factories

Objective scoring to reduce subjective judgments

Efficient audit process

Traceable evidence for reporting and decision-making

| Category | Sample Audit Items | Rating / Scoring |

|---|---|---|

| Production Infrastructure | Machinery condition, automation, layout | 0–5 |

| Process & Workflow | SOP adherence, defect management | 0–5 |

| Technical Expertise | Staff certifications, skills, training programs | 0–5 |

| Maintenance & Calibration | Preventive maintenance schedules, calibration logs | 0–5 |

| Technology & Innovation | Digital systems, automation, software integration | 0–5 |

| Quality Control Systems | QC labs, testing procedures, defect tracking | 0–5 |

| Capacity Planning | Production volume, scalability | 0–5 |

| Energy & Utilities | Backup systems, energy efficiency, water treatment | 0–5 |

| Safety & Compliance | Fire, machinery safety, PPE usage | 0–5 |

| Environmental Practices | Waste management, certifications | 0–5 |

Rating Key:

5 – Excellent / Fully Compliant

4 – Good / Minor Observations

3 – Satisfactory / Needs Improvement

2 – Poor / Major Gaps

1 – Critical / Non-Compliant

0 – Not Applicable / Missing

⚖️ 8. Common Challenges & Mitigation

| Challenge | Mitigation |

|---|---|

| Outdated Machinery | Recommend upgrades, preventive maintenance, replacement plans |

| Low Workforce Competency | Staff training, certifications, and mentoring programs |

| Workflow Bottlenecks | Optimize sequencing, improve SOP adherence, introduce automation |

| Poor Maintenance Practices | Enforce maintenance schedules, calibration logs, and preventive measures |

| Inconsistent Quality Control | Standardize QC procedures, introduce digital monitoring, and audits |

| Energy & Utility Failures | Install backup power, monitor energy efficiency, ensure sustainable operations |

🧠 9. Best Practices for Effective Factory Technical Assessment

Plan Thoroughly: Define audit scope, objectives, and timeline

Use Standardized Checklists: Ensure consistency across auditors and factories

Train Assessment Teams: Equip auditors with technical, operational, and regulatory expertise

Engage Factories Positively: Position assessment as an improvement opportunity

Leverage Technology: Digital forms, dashboards, and scoring systems

Document Everything: Photos, reports, and evidence for traceability

Conduct Periodic Re-Assessments: Maintain long-term operational excellence

🔍 10. Real-World Example: Electronics Factory Assessment

Scenario: A European buyer wants to source electronic components from an Asian factory.

Audit Steps:

Pre-assessment: Reviewed machinery lists, maintenance records, SOPs

On-Site: Inspected production lines, QC labs, workflow efficiency

Staff Interviews: Assessed technical competence and training programs

Findings: Some outdated machines, workflow inefficiencies, missing QC logs

Recommendations: Equipment upgrades, staff training, process optimization

Outcome:

Factory implemented improvements

Buyer gained confidence in production readiness

Long-term partnership established with consistent quality and efficiency

Section 1: What is Validation of Production Readiness (VPR)?

A structured assessment to confirm supplier readiness for production

Evaluates operational, technical, workforce, and quality readiness

Conducted before mass production, new product launches, or post-process changes

Helps buyers mitigate risks, maintain quality, and ensure reliable order fulfillment

Visual/Icons: Factory icon, checklist icon

Section 2: Scope of Assessment

Table (Responsive for mobile/desktop):

| Area | Key Checks | Buyer Benefits |

|---|---|---|

| Production Infrastructure | Machinery condition, automation, layout, spare parts | Operational reliability, reduced downtime |

| Process & Workflow | SOP adherence, sequencing, defect management | Efficient operations, minimized errors |

| Technical Workforce | Skills, certifications, training | Competent handling of production processes |

| Material & Supply Readiness | Inventory, component quality, supplier coordination | Reduces risk of shortages |

| Quality Control Systems | QC labs, inspection points, sampling plans | Consistent product quality |

| Capacity & Scalability | Production volume, lead times | Meets order demand reliably |

| Maintenance & Reliability | Preventive maintenance, calibration logs | Minimizes equipment failures |

| Technology & Systems | ERP, automation, production tracking | Enhanced traceability |

| Safety & Compliance | Workplace safety, PPE, regulatory adherence | Operational safety and legal compliance |

| Environmental Practices | Waste management, energy efficiency | Sustainable production |

Visual Idea: Use a grid layout with icons for each area for mobile-friendly UX.

Section 3: Objectives & Benefits

Heading: Why Conduct a VPR Audit?

Visual: Icon-based bullets or infographic

Core Objectives Table:

| Objective | Purpose / Outcome |

|---|---|

| ✅ Production Readiness | Confirm operational capability for reliable orders |

| ⚙️ Workforce & Competence | Verify staff skills and certifications |

| 🏭 Process & Efficiency | Identify workflow bottlenecks |

| 🚨 Risk Identification | Highlight operational, quality, or material risks |

| 🌱 Supplier Development | Recommend process or skills improvements |

| 💡 Scalability Assurance | Confirm ability to expand production without quality loss |

| 🔧 Equipment Reliability | Reduce downtime via preventive maintenance |

Benefits Table:

| Benefit | Description |

|---|---|

| 📉 Reduced Production Risk | Minimize delays, defects, or interruptions |

| 🏭 Consistent Product Quality | Ensure compliance with specifications and standards |

| 🔍 Operational Transparency | Clear insight into supplier readiness |

| 🌍 Compliance & Safety Assurance | Verify regulations, safety, and environmental standards |

| 💡 Data-Driven Decisions | Confident sourcing and production decisions |

| 🕓 Faster Time-to-Market | Reduce lead times through validated readiness |

Section 4: When to Conduct VPR

Heading: Ideal Times for VPR Audit

Content:

Before mass production or new product launch

After machinery, process, or line changes

During supplier onboarding

Following incidents affecting production or quality

As part of periodic supplier monitoring

Visual: Timeline or step icon graphics

Section 5: VPR Process Flow

Heading: How We Conduct VPR

Flowchart Graphic:

Preparation ➜ On-Site / Remote Evaluation ➜ Reporting & Analysis ➜ Follow-Up & Monitoring

Table for Details:

| Stage | Key Activities |

|---|---|

| Preparation | Review SOPs, machinery, materials; define scope; prepare checklist |

| On-Site / Remote Evaluation | Inspect production lines, staff competency, QC systems |

| Reporting & Analysis | Document findings, rate readiness, recommend improvements |

| Follow-Up & Monitoring | Track corrective actions, monitor improvements, periodic reassessment |

Section 6: Production Readiness Checklist & Rating

Table:

| Category | Sample Audit Items | Rating / Score |

|---|---|---|

| Production Infrastructure | Machinery, layout, automation | 0–5 |

| Process & Workflow | SOP compliance, defect management | 0–5 |

| Technical Workforce | Skills, certifications, training | 0–5 |

| Material & Supply | Inventory, quality, supplier coordination | 0–5 |

| Quality Control | QC labs, inspections, sampling | 0–5 |

| Capacity & Scalability | Production volume, lead times | 0–5 |

| Maintenance & Reliability | Preventive maintenance, calibration | 0–5 |

| Technology & Systems | ERP, automation, monitoring | 0–5 |

| Safety & Compliance | Workplace safety, PPE, regulations | 0–5 |

| Environmental Practices | Waste management, energy efficiency | 0–5 |

Rating Key:

5 – Excellent / Fully Ready

4 – Good / Minor Observations

3 – Satisfactory / Needs Improvement

2 – Poor / Major Gaps

1 – Critical / Not Ready

0 – Not Applicable / Missing

Section 7: Challenges & Mitigation

| Challenge | Mitigation |

|---|---|

| Material shortages | Pre-order planning, buffer stock, supplier coordination |

| Equipment downtime | Preventive maintenance, backups |

| Workforce skill gaps | Training, certification programs |

| Workflow inefficiencies | SOP optimization, automation |

| Quality failures | Standardized QC checks, digital monitoring |

| Safety & compliance gaps | Safety audits, PPE enforcement |

| Environmental non-compliance | Certifications, sustainable practices |

Section 8: Best Practices

Plan audit objectives and scope clearly

Use standardized checklists

Train audit teams thoroughly

Engage suppliers as partners

Leverage technology: dashboards, logs, scoring systems

Maintain documented evidence

Conduct periodic reassessments

Section 9: Case Study

Scenario: European buyer launching a new electronic product with an Asian supplier

Assessment: SOPs, machinery, material stock, QC procedures, staff competence

Findings: Minor workflow bottlenecks, missing QC logs

Recommendations: Material pre-planning, staff training, workflow optimization

Outcome: Corrective actions implemented, production started on time, quality ensured, buyer confidence enhanced

📘 1. What is Social Compliance Audit?

A Social Compliance Audit (SCA) is a systematic assessment of a supplier’s adherence to labor standards, ethical practices, human rights, and workplace safety. It ensures suppliers comply with SA8000, SMETA, BSCI, and local labor laws, protecting workers and mitigating operational and reputational risks.

⚙️ 2. Criteria Covered / Typical Areas Assessed

| Category | Key Checks | Buyer’s Benefits |

|---|---|---|

| Labor Rights | Working hours, wages, overtime, child & forced labor | Safeguard workforce welfare; ensure legal compliance |

| Health & Safety | PPE, workplace hazards, emergency preparedness | Reduce accidents; ensure safe environment |

| Ethics & Anti-Bribery | Policies, grievance mechanisms | Mitigate legal & reputational risks |

| Management Systems | Training, monitoring, compliance programs | Ensure systematic and sustainable compliance |

| Freedom of Association | Union rights, collective bargaining | Promote fair labor practices |

| Discrimination & Harassment | Gender equality, anti-harassment policies | Foster inclusive and respectful workplaces |

| Environmental Practices | Waste management, energy efficiency | Support sustainability and CSR commitments |

🧭 3. What a Social Compliance Audit Covers

Labor Standards: Wage, working hours, child/forced labor compliance

Health & Safety: Fire safety, PPE, ergonomics, sanitation

Ethical Practices: Anti-corruption, grievance mechanism, transparency

Management Systems: Policy implementation, training, monitoring

Freedom of Association: Union and worker rights, grievance handling

Discrimination & Harassment Prevention: Gender equality, anti-harassment

Environmental Responsibility: Waste management, energy usage, sustainability

🎯 4. Objectives & Key Benefits

Core Objectives

| Objective | Purpose / Outcome |

|---|---|

| ✅ Verify Compliance | Ensure suppliers follow labor laws and international standards |

| 🧩 Assess Workplace Systems | Examine HR policies, safety systems, grievance mechanisms |

| ⚖️ Identify Risks Early | Detect non-compliance, unsafe conditions, ethical gaps |

| 🌱 Support Supplier Development | Recommend corrective actions for efficiency and ethics |

| 🔍 Enhance Transparency | Provide insight into operations and workforce management |

Key Benefits

| Benefit | Impact |

|---|---|

| 📉 Reduced Supply Chain Risk | Prevent disruptions from labor or ethical violations |

| 🏭 Safer & Fair Work Environment | Ensure worker health, safety, and welfare |

| 🔍 Enhanced Supplier Transparency | Clear insights into labor practices and policies |

| 🌍 Ethical & Social Assurance | Compliance with labor standards, human rights, CSR |

| 💡 Strategic Decision-Making | Informed sourcing and supplier development decisions |

🕓 5. When to Conduct

Before Supplier Onboarding: Confirm compliance prior to partnership

During Ongoing Partnerships: Monitor continuous compliance

After Critical Incidents: Investigate accidents or grievances

📊 6. Steps to Conduct Social Compliance Audit

| Stage | Key Activities |

|---|---|

| Preparation | Collect labor records, certifications, HR policies; define scope & criteria |

| On-Site / Remote Audit | Inspect facilities, observe working conditions, interview staff, review documents |

| Reporting & Analysis | Document findings, rate performance, identify non-compliance, recommend actions |

| Follow-Up & Monitoring | Track corrective actions, schedule reassessments, ensure continuous compliance |

✅ 7. Social Compliance Checklist & Rating

| Category | Sample Items | Rating / Scoring |

|---|---|---|

| Labor Rights | Wages, hours, child/forced labor | 0–5 |

| Health & Safety | PPE, emergency procedures, ergonomics | 0–5 |

| Ethics & Anti-Bribery | Policies, grievance systems | 0–5 |

| Management Systems | Policies, training, monitoring | 0–5 |

| Freedom of Association | Union rights, collective bargaining | 0–5 |

| Discrimination & Harassment | Gender equality, anti-harassment | 0–5 |

| Environmental Practices | Waste management, energy usage | 0–5 |

Rating Key:

5 – Excellent / Fully Compliant | 4 – Good / Minor Observations | 3 – Needs Improvement | 2 – Poor / Major Gaps | 1 – Critical / Non-Compliant | 0 – N/A or Missing

⚖️ 8. Common Challenges & Mitigation

| Challenge | Mitigation |

|---|---|

| Incomplete or False Records | Verify via databases or third-party validation |

| Worker Reluctance | Conduct confidential interviews; build trust |

| Diverse Standards | Align local labor laws with international requirements |

| Complex Supply Chains | Trace sub-suppliers to avoid hidden risks |

| Subjective Assessments | Use standardized checklists & rating systems |

🧠 9. Best Practices

Plan audit scope & objectives thoroughly

Use standardized checklists across sites

Train auditors on laws, culture, and compliance standards

Engage suppliers positively

Use digital dashboards and scoring systems

Document all evidence for traceability

🔍 10. Real-World Example: Apparel Manufacturing

Scenario: European brand sourcing garments from an Asian factory

Audit Steps:

Pre-audit: Reviewed labor policies, wages, SA8000 certifications

On-site: Observed working conditions, PPE, emergency preparedness

Interviews: Verified worker rights, grievance mechanisms

Findings:

Minor overtime discrepancies, incomplete training records

Recommendations: Improve documentation, training, and grievance handling

Outcome:

Corrective actions implemented, factory aligned with labor standards, buyer confidence strengthened

📘 1. What is Ethical Compliance Audit?

An Ethical Compliance Audit (ECA) is a systematic assessment of a supplier or factory to ensure adherence to ethical business practices, anti-bribery policies, corporate social responsibility (CSR), and human rights standards. This audit evaluates policies, procedures, and actual practices to ensure suppliers operate with integrity and in alignment with international ethical standards, minimizing legal, operational, and reputational risks.

⚙️ 2. Criteria Covered / Typical Areas Assessed

| Category | Key Checks | Buyer’s Benefits |

|---|---|---|

| Anti-Corruption & Bribery | Policies, training, transaction records | Prevent financial and reputational risks; ensure legal compliance |

| Corporate Governance | Organizational structure, management oversight | Ensure transparency and proper decision-making |

| Conflict of Interest Management | Supplier relationships, related-party transactions | Avoid unethical business dealings |

| CSR & Sustainability Programs | Environmental initiatives, social programs | Enhance brand reputation and global compliance |

| Ethical Procurement | Supplier selection criteria, subcontractor oversight | Ensure integrity across the supply chain |

| Whistleblower & Grievance Mechanisms | Reporting channels, protection policies | Encourage reporting of unethical practices safely |

| Fair Trade Practices | Compliance with trade laws and agreements | Protect company from regulatory violations |

🧭 3. What an Ethical Compliance Audit Covers

Anti-Corruption & Bribery: Policies, training programs, compliance with local and international anti-bribery laws

Corporate Governance: Transparency, decision-making, management oversight

Conflict of Interest: Identification and mitigation of personal or business conflicts

CSR & Sustainability: Social programs, environmental responsibility, charitable initiatives

Ethical Procurement: Supplier selection, contract fairness, subcontractor management

Whistleblower & Grievance Systems: Confidential channels, protection policies, follow-up

Fair Trade Practices: Adherence to trade laws, avoidance of unfair practices

🎯 4. Objectives & Key Benefits

Core Objectives

| Objective | Purpose / Outcome |

|---|---|

| ✅ Verify Ethical Compliance | Ensure suppliers comply with anti-bribery laws, CSR, and ethical standards |

| 🧩 Assess Governance Systems | Examine management oversight, reporting lines, and internal controls |

| ⚖️ Detect Risks Early | Identify potential unethical behavior, conflicts, or corruption risks |

| 🌱 Promote Ethical Supplier Practices | Recommend corrective actions to improve policies and practices |

| 🔍 Enhance Transparency & Accountability | Ensure documented proof of ethical practices and supplier integrity |

Key Benefits

| Benefit | Impact |

|---|---|

| 📉 Mitigated Compliance Risks | Reduce exposure to fines, sanctions, and reputational damage |

| 🏢 Stronger Corporate Governance | Clear structures and policies to ensure integrity |

| 🔍 Transparent Supply Chain | Visibility into suppliers’ ethical practices and decision-making |

| 🌍 CSR Alignment | Ensure suppliers contribute positively to social and environmental initiatives |

| 💡 Strategic Sourcing Decisions | Empower buyers to select partners aligned with ethical standards |

🕓 5. When to Conduct

Before Supplier Onboarding: Ensure suppliers meet ethical standards prior to engagement

During Ongoing Partnerships: Monitor continued ethical compliance and corporate behavior

After Reports of Misconduct: Investigate potential unethical practices or breaches

📊 6. Steps to Conduct Ethical Compliance Audit

| Stage | Key Activities |

|---|---|

| Preparation | Collect policies, certifications, CSR reports, transaction records; define audit scope |

| On-Site / Remote Audit | Inspect offices and operations, interview management and staff, review records |

| Reporting & Analysis | Document findings, evaluate risks, recommend corrective measures |

| Follow-Up & Monitoring | Track implementation of corrective actions, reassess periodically |

✅ 7. Ethical Compliance Checklist & Rating

| Category | Sample Items | Rating / Scoring |

|---|---|---|

| Anti-Corruption & Bribery | Policies, training, transactional records | 0–5 |

| Corporate Governance | Management structure, oversight, reporting | 0–5 |

| Conflict of Interest | Supplier relationships, personal business links | 0–5 |

| CSR & Sustainability | Environmental & social programs, initiatives | 0–5 |

| Ethical Procurement | Supplier selection, subcontractor management | 0–5 |

| Whistleblower / Grievance Systems | Reporting channels, protection policies | 0–5 |

| Fair Trade Practices | Compliance with trade laws, fair dealing | 0–5 |

Rating Key:

5 – Excellent / Fully Compliant | 4 – Good / Minor Observations | 3 – Needs Improvement | 2 – Poor / Major Gaps | 1 – Critical / Non-Compliant | 0 – Not Applicable or Missing

⚖️ 8. Common Challenges & Mitigation

| Challenge | Mitigation |

|---|---|

| Limited Policy Documentation | Request formal policies and conduct staff interviews |

| Supplier Resistance | Explain audit purpose and benefits; promote cooperation |

| Conflicting Local vs International Standards | Align supplier practices with both local laws and global buyer requirements |

| Hidden Conflicts of Interest | Conduct detailed interviews and transaction reviews |

| Inconsistent CSR Reporting | Use standardized assessment frameworks for evaluation |

🧠 9. Best Practices

Establish clear audit scope and objectives

Use standardized checklists for consistency

Train auditors on ethical standards and regulations

Engage suppliers positively, highlighting benefits

Utilize digital systems for reporting and scoring

Document all evidence for accountability and traceability

🔍 10. Real-World Example: Electronics Supplier

Scenario: A European buyer sourcing from an Asian electronics supplier

Audit Steps:

Pre-audit: Collected anti-bribery policies, CSR reports, transaction records

On-site: Verified governance practices, interviewed management, reviewed procurement practices

Findings: Minor conflicts of interest and incomplete CSR reporting

Recommendations: Improve policy documentation, enhance staff training

Outcome:

Supplier implemented corrective actions, strengthened governance and CSR programs

Buyer achieved higher confidence in ethical compliance

📘 1. What is an Environmental Audit?

An Environmental Audit (EA) is a structured assessment of a supplier’s operations to ensure compliance with environmental regulations, sustainability standards, and eco-friendly practices. The audit evaluates how suppliers manage waste, energy, emissions, water usage, and other environmental impacts. Its main purpose is to help buyers ensure that their supply chain operates responsibly, meets global environmental standards, and minimizes ecological risks.

⚙️ 2. Criteria Covered / Typical Areas Assessed

| Category | Key Checks | Buyer’s Benefits |

|---|---|---|

| Waste Management | Hazardous/non-hazardous waste segregation, disposal methods | Reduce environmental impact; ensure legal compliance |

| Energy Usage & Efficiency | Electricity, fuel consumption, energy-saving initiatives | Improve efficiency, reduce carbon footprint |

| Water Management | Consumption, recycling, wastewater treatment | Ensure sustainable water practices and regulatory compliance |

| Air & Emission Control | VOCs, dust, greenhouse gases, exhaust treatment | Minimize environmental pollution and regulatory penalties |

| Environmental Certifications | ISO 14001, local environmental permits | Assurance of sustainable practices and compliance |

| Chemical & Hazardous Material Handling | Storage, labeling, safety procedures | Prevent environmental hazards and legal violations |

| Environmental Policies & Training | Staff awareness, eco-friendly initiatives | Promote culture of sustainability and responsibility |

🧭 3. Comprehensive Environmental Audit Covers

Waste Management: Proper segregation, storage, and disposal of waste; recycling and reuse initiatives

Energy Efficiency: Evaluation of electricity, fuel, and other energy usage; implementation of energy-saving technologies

Water Usage: Assessment of consumption, recycling, and wastewater treatment systems

Air Emissions: Monitoring of pollutants, dust, VOCs, and greenhouse gas emissions

Hazardous Materials: Safe storage, handling, and disposal of chemicals and hazardous substances

Environmental Management Systems: Verification of ISO certifications and documented environmental policies

Training & Awareness: Staff training programs, green initiatives, and compliance with environmental laws

🎯 4. Objectives & Key Benefits

Core Objectives

| Objective | Purpose / Outcome |

|---|---|

| ✅ Ensure Environmental Compliance | Verify suppliers adhere to local and international environmental laws |

| 🌱 Promote Sustainability | Assess energy, water, and waste management practices for environmental responsibility |

| ⚠️ Identify Environmental Risks Early | Detect potential hazards, pollution, or non-compliance issues |

| 💡 Improve Operational Efficiency | Recommend eco-friendly initiatives that reduce costs and resource consumption |

| 🔍 Enhance Transparency & Reporting | Document environmental performance for buyers and stakeholders |

Key Benefits

| Benefit | Impact |

|---|---|

| 🌍 Regulatory Compliance | Avoid fines, sanctions, or legal penalties |

| 📉 Reduced Environmental Risks | Minimize impact on ecosystems, air, water, and soil |

| 🔋 Improved Resource Efficiency | Reduce energy and water consumption, lowering operational costs |

| 🌱 Sustainability Assurance | Ensure suppliers implement responsible environmental practices |

| 💡 Informed Decision-Making | Enable buyers to select environmentally responsible suppliers |

🕓 5. When to Conduct

Before Supplier Onboarding: Confirm compliance with environmental regulations and standards

During Ongoing Partnerships: Monitor environmental practices and sustainability initiatives

After Environmental Incidents: Evaluate and address non-compliance or hazards

📊 6. Steps to Conduct Environmental Audit

| Stage | Key Activities |

|---|---|

| Preparation | Collect environmental policies, permits, energy/water usage records; define audit scope |

| On-Site / Remote Audit | Inspect production facilities, waste management systems, and energy practices; interview staff |

| Reporting & Analysis | Document findings, evaluate compliance and risk areas, recommend improvements |

| Follow-Up & Monitoring | Track corrective actions, reassess periodically, monitor sustainability improvements |

✅ 7. Environmental Audit Checklist & Rating

| Category | Sample Audit Items | Rating / Scoring |

|---|---|---|

| Waste Management | Segregation, disposal, recycling | 0–5 |

| Energy Usage | Electricity, fuel consumption, efficiency measures | 0–5 |

| Water Management | Consumption, treatment, recycling | 0–5 |

| Air & Emissions | VOCs, dust, greenhouse gases | 0–5 |

| Chemical Handling | Storage, labeling, safety | 0–5 |

| Certifications & Policies | ISO 14001, local permits | 0–5 |

| Staff Training & Awareness | Environmental programs and knowledge | 0–5 |

Rating Key:

5 – Excellent / Fully Compliant | 4 – Good / Minor Observations | 3 – Satisfactory / Needs Improvement | 2 – Poor / Major Gaps | 1 – Critical / Non-Compliant | 0 – Not Applicable or Missing

⚖️ 8. Common Challenges & Mitigation

| Challenge | Mitigation |

|---|---|

| Incomplete Environmental Records | Collect all documentation, validate through site inspections |

| Supplier Resistance | Explain benefits of compliance and sustainability; promote collaboration |

| Diverse Regulatory Standards | Align local practices with global buyer environmental expectations |

| Complex Waste & Chemical Management | Verify sub-suppliers and hazardous material handling |

| Lack of Awareness | Conduct training programs and workshops on environmental policies |

🧠 9. Best Practices

Plan audit scope and objectives clearly

Use standardized checklists for consistent evaluation

Train audit teams on environmental regulations and best practices

Engage suppliers constructively, emphasizing sustainability benefits

Leverage digital tools for reporting, scoring, and monitoring

Document evidence for accountability and future reference

🔍 10. Real-World Example: Toy Factory Environmental Audit

Scenario: A European toy manufacturer sourcing from an Asian supplier wanted to ensure environmental compliance and sustainability.

Audit Steps:

Pre-Audit: Collected ISO 14001 certification, environmental policy documents, and energy/water consumption records

On-Site Inspection: Checked production areas, waste disposal systems, chemical storage, water treatment facilities, and energy efficiency measures

Staff Interviews: Evaluated awareness of environmental policies and practices

Findings: Inefficient energy usage in manufacturing lines and incomplete hazardous material handling documentation

Recommendations: Upgrade energy-efficient machinery, implement proper chemical storage procedures, and conduct staff environmental training

Outcome:

Supplier implemented corrective measures, improved energy efficiency, and strengthened waste management

Buyer achieved sustainable and compliant supply chain assurance, supporting global environmental goals

📘 Fire & Safety Audit – Global Overview

A Fire & Safety Audit (FSA) is a structured assessment of a factory or supplier’s workplace safety, fire prevention systems, emergency preparedness, and compliance with local and international safety regulations. The audit ensures that operations meet both legal requirements and global buyer expectations, safeguarding employees, minimizing operational risks, and improving overall workplace safety culture.

⚙️ 1. Key Criteria Covered / Typical Areas Assessed

| Category | Key Checks | Buyer’s Benefits |

|---|---|---|

| Fire Safety Systems | Fire alarms, extinguishers, sprinklers, fire exits, evacuation plans | Reduce fire hazards, ensure readiness during emergencies |

| Workplace Safety | Machinery safety, chemical handling, hazard labeling, ergonomics | Minimize accidents, injuries, and liability risks |

| Emergency Preparedness | Emergency response plans, drills, first-aid readiness | Ensure effective response to incidents |

| Regulatory Compliance | Local fire codes, occupational health & safety laws, building regulations, international standards (ISO 45001, NFPA) | Avoid legal penalties, maintain compliance across regions |

| Training & Awareness | Employee safety training, fire drills, signage | Build safety culture and employee readiness |

| Incident Reporting & Record-Keeping | Accident logs, near-miss reports, safety inspections | Provide traceable documentation for accountability |

| Safety Policies & Management Systems | Safety manuals, risk assessments, SOPs | Ensure systematic safety management |

Regional Note: QIV audits consider local regulations such as Bangladesh Fire Safety Codes & Labour Act (Asia), OSHA/ISO standards (Africa/Europe), Local Building Codes & Labour Laws (Latin America), and NFPA, EU Fire Safety directives (Europe).

🧭 2. Comprehensive Fire & Safety Audit Covers

Fire Safety Systems: Alarms, extinguishers, sprinklers, fire exits, emergency signage, and evacuation plans

Workplace Safety Practices: Machinery safety, chemical handling, ergonomics, hazard control

Emergency Preparedness: Fire drills, first-aid readiness, and emergency response teams

Training & Awareness: Employee knowledge, ongoing training, participation in drills

Compliance & Documentation: Verification against local and international safety codes

Incident Management: Review past accidents, near-misses, and corrective actions

🎯 3. Objectives & Key Benefits

Core Objectives

| Objective | Purpose / Outcome |

|---|---|

| ✅ Legal & Regulatory Compliance | Ensure adherence to local fire codes, occupational health laws, building codes, and international standards |

| 🔥 Risk Mitigation | Identify hazards and prevent accidents, fire incidents, and operational disruptions |

| 🚨 Emergency Preparedness | Evaluate readiness to respond effectively to incidents |

| 🌱 Safety Culture | Train employees, raise awareness, and promote proactive safety practices |

| 💡 Continuous Improvement | Provide actionable recommendations to enhance workplace safety systems |

Key Benefits

| Benefit | Impact |

|---|---|

| 🛡 Reduced Operational Risks | Minimize accidents, injuries, and production downtime |

| 🧯 Enhanced Fire Safety | Ensure functional fire prevention and emergency systems |

| 👷 Employee Protection | Safeguard staff and reduce liability |

| 🔍 Improved Compliance & Transparency | Align with local regulations and international standards |

| 💡 Informed Strategic Decisions | Enable buyers to assess supplier safety performance and reduce supply chain risks |

🕓 4. When to Conduct

Before Supplier Onboarding: Verify legal and operational compliance

During Operations: Monitor ongoing compliance with safety standards

After Incidents: Assess causes, emergency response, and corrective actions

📊 5. Steps to Conduct Fire & Safety Audit

| Stage | Key Activities |

|---|---|

| Preparation | Collect safety manuals, permits, incident records; define scope & criteria |

| On-Site / Remote Inspection | Check fire alarms, extinguishers, sprinklers, exits, signage, machinery safety; observe operations |

| Staff Interviews | Evaluate knowledge of safety policies, emergency procedures, and training |

| Reporting & Analysis | Document findings, highlight risks, recommend corrective actions |

| Follow-Up & Monitoring | Track implementation of recommendations; schedule reassessment |

✅ 6. Fire & Safety Audit Checklist & Rating

| Category | Sample Audit Items | Rating / Scoring |

|---|---|---|

| Fire Safety Systems | Alarms, extinguishers, sprinklers, exits | 0–5 |

| Workplace Safety | Machinery, chemical handling, hazard labeling | 0–5 |

| Emergency Preparedness | Drills, evacuation plans, first-aid readiness | 0–5 |

| Training & Awareness | Employee fire & safety training, drills | 0–5 |

| Regulatory Compliance | Local & international fire, labour, building codes | 0–5 |

| Incident Reporting | Accident logs, corrective actions, near-miss records | 0–5 |

| Safety Policies & Management | Manuals, risk assessments, SOPs | 0–5 |

Rating Key:

5 – Excellent / Fully Compliant | 4 – Good / Minor Observations | 3 – Satisfactory / Needs Improvement | 2 – Poor / Major Gaps | 1 – Critical / Non-Compliant | 0 – Not Applicable or Missing

⚖️ 7. Common Challenges & Mitigation

| Challenge | Mitigation |

|---|---|

| Incomplete documentation | Verify manuals, SOPs, permits, and incident reports |

| Low staff awareness | Conduct regular training and fire drills |

| Non-functional safety equipment | Routine inspections, maintenance, and replacement |

| Complex facilities | Ensure clear evacuation routes, exits, and signage |

| Resistance to audit | Communicate benefits and adopt collaborative approach |

🧠 8. Best Practices

Define clear audit objectives and scope

Use standardized checklists for global consistency

Train auditors on local and international fire & safety standards

Engage employees and promote safety culture

Leverage digital reporting and tracking tools

Maintain detailed documentation for accountability

🔍 9. Real-World Example: Toy Factory Fire & Safety Audit (Latin America)

Scenario: A North American buyer requested a Fire & Safety Audit for a toy manufacturing plant in Mexico to ensure compliance with local regulations and international buyer standards.

Audit Steps:

Pre-Audit: Gathered safety manuals, incident logs, fire permits

On-Site Inspection: Verified alarms, extinguishers, sprinklers, exits, and emergency signage

Staff Interviews: Assessed knowledge of evacuation procedures and emergency response

Findings: Blocked exits, outdated fire extinguishers, lack of regular drills

Recommendations: Clear exits, replace equipment, implement quarterly drills, and train employees

Outcome:

Corrective actions implemented successfully

Improved fire safety compliance and emergency preparedness

Buyer gained confidence in supplier safety and risk mitigation

🔥 Fire & Safety Audit – Process Flow

Stage 1: Preparation

Collect relevant documentation: fire permits, safety manuals, past incident reports

Define audit scope, objectives, and criteria

Develop a tailored Fire & Safety Audit checklist

Stage 2: On-Site / Remote Inspection

Check fire safety systems: alarms, extinguishers, sprinklers, emergency exits, signage

Inspect workplace safety: machinery, chemicals, ergonomics, hazard labeling

Assess emergency preparedness: drills, first-aid readiness, emergency response teams

Observe real-time operations and employee safety practices

Stage 3: Staff Interviews

Evaluate knowledge of safety policies, emergency procedures, and training effectiveness

Assess awareness of local regulations and international standards

Stage 4: Reporting & Analysis

Document audit findings, including photos and observations

Rate supplier performance by category

Identify risks and non-compliances

Recommend corrective actions and improvements

Stage 5: Follow-Up & Monitoring

Track implementation of corrective actions

Schedule periodic reassessment of safety systems

Update records to ensure ongoing compliance and risk mitigation

🛡️ 1. What is Security Compliance Audit / CT-PAT Audit?

A Security Compliance Audit, often linked to Customs-Trade Partnership Against Terrorism (CT-PAT) requirements, is a structured assessment of a supplier’s or facility’s security protocols across the supply chain. It ensures compliance with international security standards to prevent theft, smuggling, and unauthorized access to goods and sensitive areas.

The main purpose is to protect the integrity of supply chains, minimize security risks, and enable seamless trade for companies engaging in global markets.

⚙️ 2. Criteria Covered / Typical Areas Assessed

| Category | Key Checks | Buyer’s Benefits |

|---|---|---|

| Physical Security | Perimeter security, access control, CCTV, security personnel | Minimize unauthorized access and cargo theft |

| Procedural Security | Policies on cargo handling, documentation, shipping procedures | Standardized and secure operational practices |

| Personnel Security | Background checks, employee screening, training programs | Reduce internal threats and enhance workforce reliability |

| IT & Data Security | Network security, shipment tracking systems, secure communication | Protect sensitive data and supply chain information |

| Cargo Security | Seals, locks, tamper-evident devices, container integrity | Ensure goods remain secure from origin to destination |

| Supplier & Carrier Security | Compliance of subcontractors, transporters, and logistics partners | Strengthen end-to-end supply chain protection |

🧭 3. Comprehensive Security Compliance Audit Usually Covers

Physical & Facility Security – Security fencing, restricted access, monitoring systems, fire safety compliance.

Employee & Personnel Controls – Screening, training, background verification, security awareness.

Cargo & Container Security – Seals, inspection protocols, storage practices, handling procedures.

Procedural & Operational Controls – Documentation, reporting, shipping procedures, incident response plans.

IT & Communication Security – Secure network systems, shipment tracking, data privacy.

Supplier & Carrier Verification – Evaluate third-party compliance with security standards.

🎯 4. Objectives & Key Benefits of Security Compliance Audit / CT-PAT Audit

Core Objectives

| Objective | Purpose / Expected Outcome |

|---|---|

| ✅ Verify Compliance | Ensure adherence to CT-PAT, ISO 28000, local regulations, and international security standards |

| 🧩 Assess Facility & Operations | Examine security systems, cargo handling, and operational controls |

| ⚙️ Evaluate Personnel & Training | Confirm employee awareness and effectiveness of security protocols |

| 🚨 Identify Risks Early | Detect vulnerabilities in physical, procedural, and personnel security |

| 🌱 Support Continuous Improvement | Provide actionable recommendations to enhance security practices |

Key Benefits of Conducting Security Compliance Audit

| Benefit | Description / Impact |

|---|---|

| 📉 Reduced Supply Chain Risk | Minimize theft, loss, smuggling, and disruption |

| 🏭 Enhanced Operational Integrity | Ensure safe handling, storage, and transport of goods |

| 🔍 Improved Transparency | Gain clear insight into security controls and compliance gaps |

| 🌍 Global Trade Compliance | Meet international standards such as CT-PAT, ISO 28000, and local regulations |

| 💡 Strategic Decision-Making | Make informed sourcing and logistics decisions based on verified security practices |

🕓 5. When to Conduct Security Compliance Audit

Before Onboarding Suppliers or Logistics Partners – Validate security compliance before engagement.

Periodically During Partnerships – Monitor ongoing performance and risk mitigation.

After Security Incidents or Breaches – Assess vulnerabilities immediately and implement corrective actions.

📊 6. Steps to Conduct Security Compliance / CT-PAT Audit

| Stage | Key Activities |

|---|---|

| Preparation | Collect facility documents, SOPs, personnel records; define audit scope and checklist |

| On-Site / Remote Audit | Inspect facilities, review cargo handling, access control, and security systems |

| Staff Interviews | Assess employee training, awareness, and adherence to security policies |

| Reporting & Analysis | Record findings, rate security performance, identify non-compliances, recommend improvements |

| Follow-Up & Monitoring | Track corrective actions, schedule periodic reassessments, and maintain compliance records |

✅ 7. Security Compliance Checklist & Rating

| Category | Sample Audit Items | Rating / Scoring Method |

|---|---|---|

| Physical Security | Fencing, CCTV, alarm systems, access logs | 0–5 |

| Procedural Security | SOPs, cargo handling, documentation | 0–5 |

| Personnel Security | Employee screening, training, background checks | 0–5 |

| Cargo Security | Seals, locks, container integrity, handling procedures | 0–5 |

| IT & Data Security | Network, tracking systems, data protection | 0–5 |

| Supplier & Carrier Security | Third-party compliance verification | 0–5 |

Rating Key:

5 – Excellent / Fully Compliant

4 – Good / Minor Observations

3 – Satisfactory / Needs Improvement

2 – Poor / Major Gaps

1 – Critical / Non-Compliant

0 – Not Applicable or Missing

⚖️ 8. Common Challenges & Mitigation

| Challenge | Mitigation |

|---|---|

| Incomplete or False Documentation | Verify authenticity via official databases or third-party validation |

| Employee Resistance | Explain audit purpose and promote collaborative approach |

| Diverse Regional Standards | Align local regulations with international CT-PAT/ISO 28000 requirements |

| Complex Supply Chains | Trace third-party suppliers and logistics partners for compliance gaps |

| Subjective Assessments | Use standardized checklists and scoring systems for objectivity |

🧠 9. Best Practices for Effective Security Compliance Audit

Plan Thoroughly: Define objectives, scope, and timeline

Use Standardized Checklists: Ensure consistent evaluation across auditors

Train Audit Teams: Equip auditors with technical, regulatory, and regional knowledge

Engage Partners Positively: Position audit as mutually beneficial

Leverage Technology: Use digital forms, dashboards, and reporting systems

Document Everything: Maintain photos, records, and evidence for traceability

🔍 10. Real-World Example: CT-PAT Audit in a Logistics Hub

Scenario:

A U.S.-based buyer sources goods from a South Asian logistics hub handling multiple international shipments.

Audit Steps:

Pre-audit: Reviewed SOPs, employee records, security system schematics

On-site: Inspected warehouse security, perimeter fencing, CCTV coverage, container seals

Interviews: Verified staff knowledge on cargo security and incident reporting

Findings: Minor gaps in seal integrity and employee training

Outcome:

Corrective actions implemented: staff re-training, updated seal procedures

Hub achieved CT-PAT certification, ensuring secure international shipping

Buyer confidence enhanced for long-term partnerships