INSPECTIONS, BEFORE PRODUCTION

"Before Production Inspection benefits both buyers and manufacturers by ensuring quality and readiness before mass production.

Buyers gain confidence, risk control, and assurance of compliance, while manufacturers achieve early problem detection, better efficiency, and stronger buyer trust.

It ultimately promotes quality, transparency, and smooth production for both parties."

🛡 Pre-Production Inspection (PPI)

Your Ultimate Shield Against Production Catastrophe

01. What is Pre-Production Inspection (PPI)?

A PPI is a critical, proactive quality control checkpoint performed at the manufacturing facility before any large-scale production officially commences.

Its core objective is to verify the factory’s readiness, the quality and quantity of all raw materials and components, and the clarity of production planning against your approved specifications. It’s the essential first step to confirm that everything is aligned for a defect-free, efficient production run.

🔴 Your Ultimate Shield Against Production Catastrophe

For global buyers, importers, and retailers, sourcing internationally presents immense opportunities — but also inherent risks.

The Pre-Production Inspection (PPI) is your earliest and most strategic intervention to safeguard your investment, timeline, and brand reputation.

Conducted before mass manufacturing begins, PPI by QIV Global acts as a comprehensive “pre-flight check,” ensuring that the foundation of your product is meticulously compliant and primed for success.

02. What Criteria Are Covered?

Our PPI is a deep, multi-faceted audit customized to your specific product and risk profile. We leave no stone unturned in verifying the integrity of your production foundation.

Inspection Areas & Key Checkpoints:

Raw Materials & Components

🔹 Quality: Verification of material composition, colour accuracy, texture, component model numbers against the Golden Sample.

🔹 Quantity: Physical count to ensure sufficient materials are on hand for the entire order.

🔹 Compliance: Review of supplier certifications for materials.

Factory Readiness & Capability

🔹 Machine Calibration: Check that all production equipment and specialized tools are correctly set up and maintained.

🔹 Storage Conditions: Assess material storage areas for temperature and humidity control.

🔹 Production Plan: Review factory’s proposed production schedule and methods.

Documentation & Sampling

🔹 Tech Pack Review: Ensure the factory fully understands the approved version of your specifications.

🔹 Golden Sample Audit: Compare raw materials and pre-production samples against your approved benchmark.

Initial Production Sample (Pilot Run)

🔹 Inspect and test the first produced units to validate the process before full-scale production.

03. Functions of PPI

The core functions of the PPI are strategically designed to empower you with control and foresight:

🔴 Prevent Rework & Scrap: Identify and rectify potential defects before costly errors enter mass production.

⚫ Validate Supplier Integrity: Ensure the factory remains transparent and compliant — no substitutions of approved materials.

🔴 Establish Production Baseline: Confirm all initial materials, processes, and documents align with your quality standards.

⚫ Safeguard Your Schedule: Verify that all inputs and capabilities are ready, minimizing risks of stoppages or delays.

04. Why PPI Is Required — The Exponential Cost of Delay for Global Buyers

For international buyers, skipping a PPI can lead to severe and escalating consequences.

The cost of fixing a defect is 10–100 times higher if discovered at the final stage (PSI) than during the PPI stage.

Without a PPI, your entire order could face 100% loss, shipment cancellations, or crippling rework costs.

PPI eliminates this unacceptable risk at minimal cost.

05. Challenges and Quality Risks

Material Substitution

🛡 Risk: Factories use cheaper, non-compliant materials.

✅ PPI Solution: Inspectors verify materials, certifications, and coordinate instant lab testing.

Schedule Delays Due to Input Issues

🛡 Risk: Factory lacks materials or receives defective components.

✅ PPI Solution: Confirm 100% of material availability and accuracy before production.

Regulatory & Safety Non-Compliance

🛡 Risk: Products may violate regulations (e.g., REACH, RoHS).

✅ PPI Solution: Verify certificates, initiate lab testing for restricted substances.

06. Benefits of Pre-Production Inspection — Your Strategic Advantage

💰 Maximum Financial Protection: Reduces risk of rework, scrap, or recalls.

✅ Guaranteed Quality from the Core: Ensures the DNA of your product is perfect and compliant.

⏱ Safeguarded Delivery Schedules: Prevents bottlenecks and protects launch timelines.

🌟 Enhanced Brand Reputation: Keeps defective or non-compliant products off the market.

07. Process of This Inspection — QIV Global’s Transparent Workflow

🔹 Seamless Booking: Submit your PO and specifications.

🔹 Customized Checklist Development: Tailored, risk-based checklist for your order.

🔹 Strategic Scheduling: Coordinated with your factory for ideal timing.

🔹 On-Site Audit & Verification: Conducted by local, specialized inspectors.

🔹 Rapid, Detailed Reporting: Receive photographic report within 24 hours.

🔹 Informed Decision & Action: Approve production (“Go”) or request correction (“Hold”).

08. Checkpoints Carried Out — Precision in Every Detail

🔹 Raw Material Verification: Composition, quality, colour, and certification check.

🔹 Component Specification Match: Ensure alignment with approved drawings.

🔹 Stock Quantity Audit: Confirm full material availability.

🔹 Machinery & Tooling Readiness: Verify calibration and setup.

🔹 Documentation Alignment: Review QC plans and factory work instructions.

🔹 Pilot Run Quality: Inspect first units for function and consistency.

09. What Happens After a PPI is Completed? — Your Next Steps

✅ Passed: Factory receives the official “Go” signal — proceed with mass production confidently.

⚠️ Failed: “Hold” signal issued — factory must correct all issues. A follow-up PPI confirms compliance before production resumes.

10. When It Should Be Conducted

Conduct the PPI immediately after all main raw materials and critical components arrive at the factory, and before cutting, assembly, or mass production begins.

This critical window typically falls when 0–10% of the batch is conceptually ready.

11. Case Study

Client: Global Fashion Retailer (Europe)

Factory Location: Ho Chi Minh City, Vietnam

Product: Women’s Apparel – Summer Collection

Order Quantity: 50,000 units

Background:

The client placed a large order for a new summer collection with multiple styles and fabric blends. The factory had previous experience but no recent PPI had been conducted for this particular product line. Concerns included raw material consistency, color matching, and adherence to safety regulations (REACH & Oeko-Tex).

PPI Objectives:

- Verify raw materials and trims matched the approved Golden Samples.

- Ensure factory readiness and production line calibration.

- Confirm documentation and tech packs were fully understood.

- Inspect initial production samples for compliance with specifications.

Inspection Findings:

- Raw Materials:

- 98% of fabrics matched the approved color and texture.

- Some minor deviation found in zippers; corrective action recommended.

- Factory Readiness:

- Machines and sewing lines calibrated correctly.

- Storage areas compliant, but humidity slightly above recommended for delicate fabrics — immediate corrective measures advised.

- Documentation & Sampling:

- Tech packs and cutting instructions properly implemented.

- Initial pilot run produced two defective units due to thread tension issues; corrected immediately.

- Regulatory Compliance:

- All fabrics and trims verified with certificates.

- Lab testing confirmed no restricted substances, fully REACH-compliant.

Outcome:

- ✅ The client issued a “Go” signal for mass production after minor corrective actions.

- Production proceeded without further delays or quality issues.

- Early detection prevented potential shipment rejection in Europe and avoided rework costs of over $5,000.

Key Takeaways:

- PPI ensured materials, processes, and factory readiness met expectations.

- Early pilot run allowed rapid correction of minor defects.

- PPI protected the client’s brand reputation by preventing defective products from reaching the market.

- Cost and time savings were substantial compared to detecting issues at PSI stage.

Fabric Inspection

Weaving a Flawless Future for Your Products

For global buyers, the quality of your fabric is the absolute foundation of your product. Undetected fabric defects are the most common cause of irreversible product flaws and catastrophic financial losses.

01. What is Fabric Inspection? 🔍

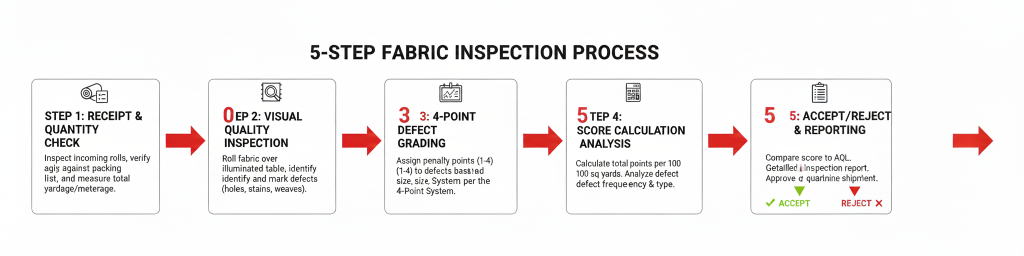

Fabric Inspection is a specialized, meticulous quality control procedure where a chosen lot of fabric rolls is thoroughly examined using a calibrated light inspection machine. This process aims to identify, measure, and score all defects against stringent international standards, primarily the globally recognized 4-Point System. It’s a technical assessment to determine if your fabric meets all specified quality parameters, color standards, and defect tolerance levels required for mass production.

02. What Criteria are Covered by Fabric Inspection? ✅

Our Fabric Inspection covers a comprehensive range of critical criteria, customized to your specific fabric type (woven, knit, printed, dyed) and product end-use:

| Inspection Area 🎯 | Key Criteria & Checkpoints (What QIV Global Verifies) |

|---|---|

| Defect Rate & Scoring | Identification: Pinpointing all fabric flaws (e.g., holes, slubs, stains, broken threads). Scoring: Applying penalty points as per the 4-Point System to determine the roll’s acceptability. |

| Color & Aesthetics | Shade Verification: Precise comparison to your approved color swatch (“Golden Sample”) under standardized lighting (D65). Shade Variation: Rigorous checking for consistency *within* rolls and *between* different rolls (Shade Banding risk). |

| Physical Dimensions | Usable Width: Accurate measurement of the fabric’s usable width, excluding damaged edges. Total Roll Length: Verification of the actual yardage against the packing list and PO to prevent shortages. |

| Structure & Construction | Weight (GSM): Measuring grams per square meter to ensure consistency. Structural Integrity: Identifying distortions like skew and bowing (off-grain fabric) which impact garment fit. |

03. Functions of Fabric Inspection 🛡

- Defect Segregation & Control: To systematically identify and isolate rolls with unacceptable defect levels, preventing them from ever reaching the cutting floor, thus minimizing material wastage.

- Inventory Accuracy & Planning: To confirm the actual usable meterage/yardage available, ensuring you have sufficient material to complete your order without costly shortages.

- Cutting Optimization: By marking defects clearly, inspection data enables cutting masters to strategically plan pattern placement, avoiding flaws and increasing fabric utilization.

- Supplier Accountability: Provides objective, documented evidence for transparent claims with fabric suppliers regarding non-compliant deliveries.

04. Why Fabric Inspection is Required? The Point of No Return 🚫

Fabric cutting represents the “point of no return” in textile manufacturing. Once fabric with undetected defects is cut, the resulting garment pieces are irreversibly flawed. This leads to massive material wastage, labor being wasted on defective goods, and final product rejection. The cost of inspection is always dramatically lower than the financial repercussions of scrapping thousands of yards of cut fabric.

05. Challenges and Quality Risks, relevant of Fabric Inspection, when the global buyer, importers & relaters from other countries. ⚠

International textile sourcing comes with unique and significant challenges that QIV Global’s Fabric Inspection directly addresses:

| Global Buyer’s Challenge/Risk ⚠ | Risk Analysis |

|---|---|

| Shade Banding & Color Inconsistency | Risk: Subtle color variations between rolls lead to unsightly “shade bands” in the final garment, causing high rejection rates at PSI. Analysis: QIV verifies shade continuity under standardized lighting, precisely isolating inconsistent rolls. |

| Yardage Shortages & Overbilling | Risk: Supplier overstates roll length, leading to unforeseen shortages, expensive re-orders, and inability to complete the full PO. Analysis: QIV uses calibrated equipment to provide certified, accurate measurements of usable quantity, ensuring you only pay for what you receive. |

| Dimensional Instability (Skew/Bowing) | Risk: Fabric that is woven or knitted off-grain (skew/bow) or shrinks excessively ruins the fit and sizing consistency of your finished product. Analysis: QIV performs technical checks to verify structural integrity, flagging unstable fabrics before they cause widespread sizing issues. |

06. Solutions 💡

QIV Global provides integrated solutions to tackle these challenges head-on:

- Precision Defect Mapping: Our reports include graphical defect maps for critical rolls, showing exact defect locations, enabling the cutting master to optimize lay plans and minimize waste.

- Certified Quantity Verification: We provide independent, verified measurements of usable fabric length and width, giving you irrefutable data for supplier claims and precise production planning.

- Advanced Shade Analysis: Our inspectors utilize specialized light boxes for consistent color assessment and can perform spectrophotometer checks for digital color data if required.

- Structural Integrity Assessment: Technical checks for GSM, yarn count, and visual identification of structural distortions like skew and bowing, ensuring the fabric behaves as expected.

07. What are the benefits of Fabric Inspection? Your Competitive Edge 👍

- Massive Cost Savings: Directly reduces fabric wastage by preventing the cutting of defective material.

- Eliminate Rework & Scrap: Prevents the need for costly post-production rework, repairs, or scrapping of finished goods due to fabric faults.

- Enhanced Cutting Efficiency: Clear defect marking empowers the cutting master to optimize lay planning, increasing material utilization by up to 5-10%.

- Stronger Supplier Accountability: Provides objective, irrefutable data for claims against fabric suppliers.

- Guaranteed Product Quality: Ensures your garments or textile products are built on a flawless foundation.

08. Process of Fabric Inspection ↺

- Booking & Sampling Plan: QIV Global defines a statistically valid sample plan (e.g., AQL-based).

- On-Site Roll Selection: Our inspector randomly selects the specified number of rolls from the received lot.

- Detailed Examination & Measurement: The inspector verifies usable width, roll length, and identifies and measures all defects.

- Scoring & AQL Application: Defects are summed and compared against the maximum allowable points (4-Point System) to determine the lot’s Pass/Fail status.

- Rapid Reporting: A comprehensive, photographic report, including defect maps and the final Pass/Fail verdict, is sent to you within 24 hours.

09. What are the Checkpoints are Carried Out? Precision in Every Thread ✔

- 4-Point System Calculation: The industry-standard method for quantifying defects.

- Usable Fabric Width Measurement: Verifying the actual width suitable for cutting.

- Total Roll Length Measurement: Confirming the supplied length matches the declared length.

- Shade Variation Check: Meticulous scrutiny for any color discrepancies within or between rolls under controlled lighting.

- Structural Check: Assessment for GSM, yarn count, and distortion (skew and bowing).

- Fabric Face & Back Verification: Confirming the correct side of the fabric is presented.

10. What Happens after Fabric Inspection is Completed? Your Decision Point ➡

The outcome of the QIV Global Fabric Inspection provides you with clear, actionable information:

- If the Lot Passes: The fabric is approved and released to the cutting department.

- If the Lot Fails: The entire lot is quarantined. You can then instruct the factory to perform **100% sorting and re-inspection** to salvage portions, negotiate a **discount** based on the quantified defects, or **reject the entire lot**.

11. When Fabric Inspection Should Conduct 🕓

Fabric Inspection should be conducted immediately upon arrival of the fabric at the factory or warehouse, and **before** the factory issues the material to the cutting department. This critical timing ensures that you have time to address supplier issues and protect your production schedule.

12. How QIV Global can help 💬

QIV Global provides independent, expert Fabric Inspection, transforming a critical risk area into a controlled, transparent process:

- Specialized Fabric Technologists: Our inspectors are textile specialists, trained extensively in the 4-Point System and defect recognition.

- Objective, Quantifiable Data: We provide concrete data (4-Point System scores, exact measurements) for clear decision-making and supplier negotiations.

- Risk-Based Approach: We tailor our inspection plans based on fabric type and risk profile, ensuring targeted, effective quality control.

- Rapid, Actionable Reports: Receive comprehensive, photographic reports within 24 hours, empowering you to make timely decisions.

⚙️ Raw Materials Inspection

The Foundation of Flawless Manufacturing

For global buyers, the quality of your raw components, materials, and trims determines the integrity, performance, and compliance of your final product. Defects in incoming materials are the most common cause of systemic production failures, regulatory non-compliance, and costly product recalls.

01. What is Raw Materials Inspection? 🔬

Raw Materials Inspection (also known as Incoming Quality Assurance or IQC) is the systematic, comprehensive assessment of all components, sub-assemblies, and materials upon arrival at the manufacturing facility and before they enter the production line. This specialized quality control process verifies the materials against the Purchase Order (PO) specifications, approved samples, technical drawings, and relevant safety/regulatory standards (e.g., RoHS, REACH, CPSIA).

02. What Criteria are Covered by Raw Materials Inspection? ✅

Our Raw Materials Inspection covers an essential range of checkpoints, customized to the material type (e.g., plastic, metal, chemical, electronic component, or accessory):

| Inspection Area 🎯 | Key Criteria & Checkpoints (What QIV Global Verifies) |

| Quantity & Logistics | Count Verification: Ensuring the actual received quantity matches the Packing List and PO. Packaging Integrity: Checking for damage during transit that may affect material quality. |

| Physical & Dimensional | Dimensional Check: Accurate measurement against technical drawings (e.g., size, diameter, thread count). Visual Inspection: Identifying surface flaws, corrosion, discoloration, scratches, or physical damage. |

| Aesthetics & Finish | Color/Shade Match: Comparing against the approved Golden Sample under standardized lighting. Surface Finish: Verifying compliance with specified textures, coatings, or treatments. |

| Functional & Technical | Material Type: Confirming the use of the specified grade (e.g., plastic resin, metal alloy, chemical compound). Functionality Check: Performing basic tests on components (e.g., zipper function, button pull-strength, gauge checks). |

03. Functions of Raw Materials Inspection 🛡

Defect Segregation & Control: To immediately isolate and quarantine non-conforming materials, preventing them from contaminating the entire production process.

Specification Compliance: To guarantee all incoming materials strictly adhere to the technical and safety requirements agreed upon with the supplier and legally mandated by the destination market.

Supplier Accountability: Provides irrefutable, objective evidence to facilitate transparent claims, returns, and corrective action plans with non-performing material suppliers.

Production Planning: Ensures the availability of verified, high-quality stock, preventing unexpected halts or delays on the assembly line.

04. Why Raw Materials Inspection is Required? The Cost Multiplier 🚫

Material defects operate on a cost multiplier effect. A flaw that costs pennies to fix at the receiving stage can cost dollars to fix after the part is assembled, and hundreds of dollars if the defect leads to a product recall or warranty claim from the end-consumer. By inspecting at the source, you dramatically reduce risk and prevent expensive re-work, re-ordering, and labor wastage downstream.

[Placeholder: Animated Infographic showing a small defective component being caught at the inspection stage (Prevention) versus causing a catastrophic failure in the final product (Failure).]

05. Challenges and Quality Risks for Global Buyers ⚠

International sourcing of raw materials introduces specific complexities that QIV Global’s IQC service is designed to mitigate:

| Global Buyer’s Challenge/Risk ⚠ | Risk Analysis |

| Material/Alloy Substitution | Risk: Supplier substitutes an expensive, specified material (e.g., 316 Stainless Steel) with a cheaper, unapproved alternative (e.g., 304). Analysis: QIV verifies certificates and performs initial chemical/physical testing (e.g., XRF analysis) to confirm the correct composition. |

| Undocumented Non-Compliance | Risk: Materials contain restricted substances (e.g., Lead, Cadmium) or fail to meet safety mandates (e.g., flammability). Analysis: QIV conducts sampling for mandatory lab testing, ensuring compliance before mass production begins. |

| Component Incompatibility | Risk: Components appear correct but have incorrect tolerances or dimensions, leading to a failure during assembly. Analysis: QIV uses precision instruments (calipers, gauges) to ensure exact dimensional compatibility for seamless fit on the assembly line. |

| Batch-to-Batch Variation | Risk: Quality differs significantly between material shipments, causing inconsistency in the final product. Analysis: QIV implements statistical sampling plans (e.g., AQL) across all batches to monitor and report on supplier consistency over time. |

06. Solutions 💡

QIV Global delivers integrated solutions to master your raw materials quality:

Verified Documentation Review: Meticulous checking of Mill Certificates, Certificates of Analysis (CoA), and Test Reports against your specifications.

Precision Measurement & Testing: Utilization of high-precision tools (calipers, micrometers, thread gauges, spectrophotometers) for quantifiable data on dimensions and aesthetics.

Pre-Lab Sampling & Coordination: Expert selection and preparation of material samples for independent laboratory safety and performance testing (e.g., Heavy Metals, strength, longevity).

Visual & Functional Verification: Thorough visual checks for defects and performance testing of moving parts, ensuring the materials are not just compliant, but fully functional.

07. What are the benefits of Raw Materials Inspection? Your Competitive Edge 👍

Maximum Risk Reduction: Mitigate the risk of costly recalls, warranty claims, and regulatory penalties.

Eliminate Assembly Downtime: Prevents line stoppages and labor wastage caused by incompatible or defective components.

Guaranteed Product Performance: Ensures your final product’s durability, safety, and function are built upon the correct foundation.

Data-Driven Sourcing: Provides objective metrics for evaluating and improving your raw material supplier base.

Clear Compliance Trail: Creates an auditable record of material verification, essential for complex regulatory environments.

08. Process of Raw Materials Inspection ↺

Booking & Sampling Plan: QIV Global defines a statistically valid sample plan (typically AQL-based, often Level II or 100% for critical components).

On-Site Material Segregation: The inspector verifies the delivery and quarantines the batch in the receiving area.

Detailed Examination & Testing: The inspector reviews documentation, performs visual checks, takes precision measurements, and conducts on-site functional tests.

Sampling for Lab Analysis (If required): Samples are sealed and shipped to an accredited lab for full safety/chemical testing.

Rapid Reporting & Verdict: A comprehensive report with photographs, measurements, and the final Pass/Fail verdict is issued.

[Placeholder: Insert Animated process flow chart showing the 5-step QIV Raw Materials Inspection process.]

09. What are the Checkpoints are Carried Out? Precision in Every Detail ✔

AQL Sample Selection: Applying the accepted quality limit (AQL) to determine the sample size.

Specification & PO Match: Verifying material name, SKU, color code, and technical properties against approved documents.

Dimensional & Tolerance Check: Precision checks on critical dimensions (using gauges, calipers, or jigs).

Functionality Test: Testing moving parts, fitment, or operational parameters where applicable.

Packaging & Labeling: Ensuring materials are correctly labeled for batch traceability and handled according to storage instructions.

Certificate Review: Validating supporting documentation (CoA, Mill Certs, etc.).

10. What Happens after Raw Materials Inspection is Completed? Your Decision Point ➡

The outcome of the QIV Global Raw Materials Inspection provides you with clear, actionable information:

If the Lot Passes: The materials are tagged as “Approved” and released to the factory’s inventory for use in production.

If the Lot Fails: The entire lot is tagged as “Rejected/Quarantined”. You can then instruct the supplier to perform 100% sorting and replacement, negotiate a discount based on the quantified defects, or reject the entire lot and source replacements.

11. When Raw Materials Inspection Should Conduct 🕓

Raw Materials Inspection must be conducted immediately upon the materials’ arrival at the facility and before the production line calls for the components. This is the last and most critical opportunity to intercept faulty goods before the cost of fixing the problem begins to multiply.

12. How QIV Global can help 💬

QIV Global provides independent, expert Raw Materials Inspection, making complex quality verification simple, transparent, and actionable:

Specialized Component Technologists: Our inspectors are trained across various industries (electronics, mechanical, chemical) to understand specific material risks.

Objective, Quantifiable Data: We provide concrete data (measurements, compliance status, photo evidence) for effective decision-making and supplier claims.

Global Lab Network Integration: We facilitate and manage the lab testing required for full regulatory and safety compliance.

Rapid, Actionable Reports: Receive comprehensive, photographic reports within 24 hours of inspection, enabling timely production decisions.

Case Study: Protecting Quality for a Global Shoe Buyer in Brazil

To illustrate the critical necessity of Raw Materials Inspection (IQC), consider the case of a major European footwear brand sourcing high-end leather boots from a large factory in the Sinos Valley region of Rio Grande do Sul, Brazil.

The Challenge: Leather Material Substitution & Non-Compliance ⚠️

The buyer specified premium, chrome-free, certified Brazilian leather with a specific thickness ($1.8 \text{ mm}$ to $2.0 \text{ mm}$) and a guaranteed pull-up finish for its latest collection. This material choice was critical to the final product’s quality, durability, and ethical sourcing claims.

Supplier Risk: The Brazilian leather supplier, facing cost pressures, substituted a portion of the delivery with a slightly cheaper, thinner leather ($1.5 \text{ mm}$ to $1.7 \text{ mm}$) that also lacked the required pull-up finish.

Compliance Risk: The substitute leather did not carry the required chrome-free certification, raising a significant REACH/EU regulatory compliance risk for the final finished goods.

QIV Global’s Intervention: Precision IQC 🔎

QIV Global was engaged to perform a comprehensive Raw Materials Inspection (IQC) immediately upon the arrival of the leather shipment at the shoe factory.

| Inspection Area | QIV Action & Finding | Outcome if Not Caught |

| Material Verification | Checked Documentation: The inspector flagged missing/incomplete chrome-free CoAs (Certificate of Analysis) for 35% of the rolls. | Final products would have been seized at EU customs due to non-compliant materials, leading to $100\%$ rejection and legal action. |

| Physical Dimensions | Thickness Measurement: Using a calibrated digital caliper on an AQL sample, the inspector found a consistent $0.3 \text{ mm}$ to $0.5 \text{ mm}$ deviation (too thin) across the uncertified rolls. | Boots would fail internal durability tests, leading to premature structural breakdown and mass warranty claims. |

| Aesthetics & Finish | Visual & Hand-Feel Check: The inspector confirmed the lack of the specified ‘pull-up’ effect and noted a visible difference in color consistency between the compliant and non-compliant rolls. | The entire high-end collection would be aesthetically compromised, resulting in retailer rejection and severe brand damage. |

The Result: Savings and Accountability ✅

The QIV Global Raw Materials Inspection report provided the global buyer with irrefutable, quantifiable evidence of material non-conformity before a single piece of leather was cut.

Immediate Cost Avoidance: The buyer immediately rejected the 35% non-compliant lot (equating to over 5,000 pairs of shoes) and initiated a claim for replacement with the approved material, saving tens of thousands of dollars in wasted labor and material.

Regulatory Protection: The compliance risk was completely eliminated, safeguarding the brand’s reputation and preventing potential regulatory fines and product seizures in the European market.

Why partner with QIV ?

Why partner with QIV ?

- Global Reach, Local Acumen: Our local teams speak the language, understand regional manufacturing nuances, and are adept at identifying country-specific risks.

- Zero Tolerance, Maximum Assurance: Our philosophy for PPI is preventative. We scrutinize every detail with a ‘zero tolerance’ approach to ensure your production starts right.

- Actionable, Rapid Intelligence: We deliver objective, data-driven reports within 24 hours, empowering you to make critical decisions swiftly.

- Unbiased Third-Party Verification: Our reports are completely impartial and transparent, free from manufacturer influence.

Payment

QIV Global offers clear, competitive, and transparent fixed-rate pricing for PPI services, ensuring no hidden costs or surprises. Payment is typically processed according to your signed service agreement, usually prior to the final report release.

Our Industries

Our Industries

QIV Global’s expertise spans a diverse and extensive portfolio of industries:

- Apparel & Textiles: Apparels, Textiles, Tent

- Footwear & Leather Goods: Leather, Footwear Products, Bag & Belt

- Food & Agriculture: National food, Canned & Packaging Food

- Electronics & Machinery: Electrical Products, Electronics Products, Watch, Clock & Time Machine, Mobile & Accessories

- Home Goods & Furnishings: Furnitures, Ceramics, Hard Goods

- Gifts, Crafts & Toys: Jute & Jute products, Handicrafts Products, Toys & Kids Items, Jewellery

- Miscellaneous: Luggage & Packaging, Bi-Cycle, Eye glass & Frame

Countries, our coverage

Countries, our coverage

QIV Global has a robust presence across all major global manufacturing hubs, ensuring seamless coverage for your supply chain:

| South Asia | Bangladesh, India, Pakistan, Sri Lanka |

| China & Southeast Asia | China, Vietnam, Indonesia, Cambodia, Myanmar |

| Middle East | Jordan, UAE |

| Africa | Egypt, Tunisia, Morocco, Kenya, Ethiopia, Madagascar, Mauritius, Ghana, Togo, Algeria, Libya, Rwanda, Tanzania, Uganda, Lesotho |

| Europe | UK, France, Germany, Spain, Italy, Netherlands, Poland, Latvia, Slovenia, Romania, Bulgaria, Portugal |

| North America | US, Canada |

| Latin America | Brazil, Mexico, Argentina, Peru, Colombia |